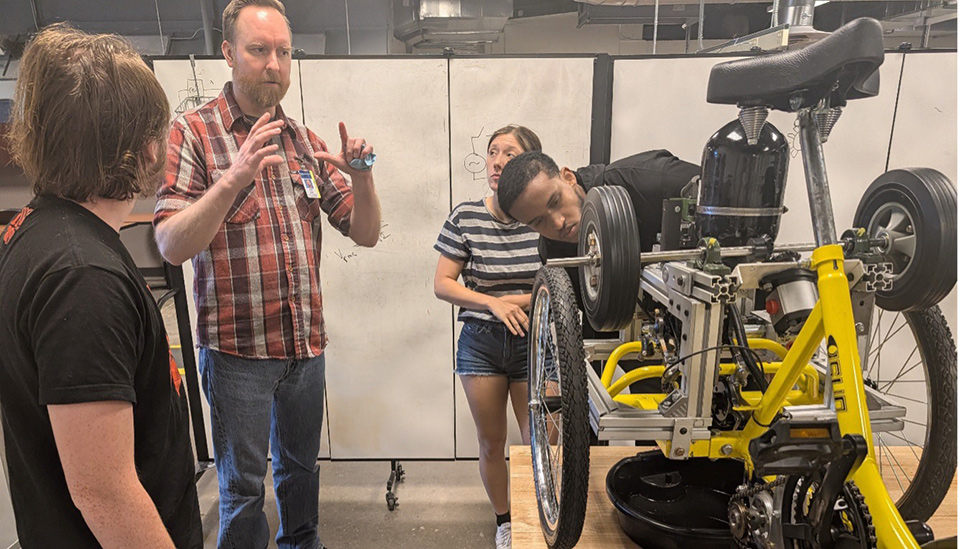

Each year, the National Fluid Power Association (NFPA) hosts the Fluid Power Vehicle Challenge. Students from Twin Cities Engineering (TCE) have participated in this challenging event for several years. This past year, TCE worked exclusively at the SPC campus. This teamwork enabled engineering students and trades students to share ideas and create new designs before competing in the Upper Midwest.

During the Spring 2025 semester, our SPC machining students genuinely embraced the challenge of transforming TCE’s ideas into parts that fulfill manufacturing needs. After TCE students designed the blueprints, SPC faculty guided them through subsequent steps, just as they would in class, aiming to find ways to make the parts easier to machine. The students pinpointed features that caused unnecessary tool changes or awkward setups and modified those areas to ensure the workflow on the CNC machines remained smooth and consistent. A crucial part of the project was understanding how small adjustments can make a part not only stronger but also more efficient and cost-effective to produce. In addition to power-vehicle components, the students also assisted in manufacturing parts for a bike-transmission system, applying the same problem-solving approach.

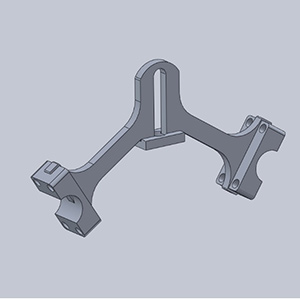

One example was provided by Sam Hansen in TCE, who modeled a set of custom transmission brackets in SolidWorks. Once Sam finalized the geometry, our SPC students took over and machined the parts to print. These brackets were more than just simple plates; they were responsible for keeping the chain tracking straight. Since the transmission replaced the rear hub on a tricycle, the team also machined a custom gear, ensuring that the bolt circles and diameters matched, so that the chain and sprockets lined up perfectly. SPC’s CNC Toolmaking students provided TCE with the support, equipment, and metrology tools they needed to make everything fit together with the precision the project demanded.

The bike project became popular on campus. Students tested it in the parking lot, and many from the campus community came to see the work. Students tested it in the parking lot, and faculty came to see the work. This team received the NFPA Judge’s Choice award for Design for their regenerative brake design. This bike project was one of several projects that received an Innovative Partnering and Collaboration award at the recent Minnesota State – Academic and Student Affairs (ASA) annual conference.

These collaborations benefit students in numerous ways. TCE students learn to clearly explain their designs and consider how easy they are to produce. SPC students learn to meet design requirements using the tools and improvements they suggested. Both groups get to see their ideas come to life and work in real situations.

Fluid power technology, which utilizes liquids or air to generate movement, is present everywhere. It’s used in items like airplanes, farm equipment, construction machinery, medical devices, packaging systems, and even amusement rides.