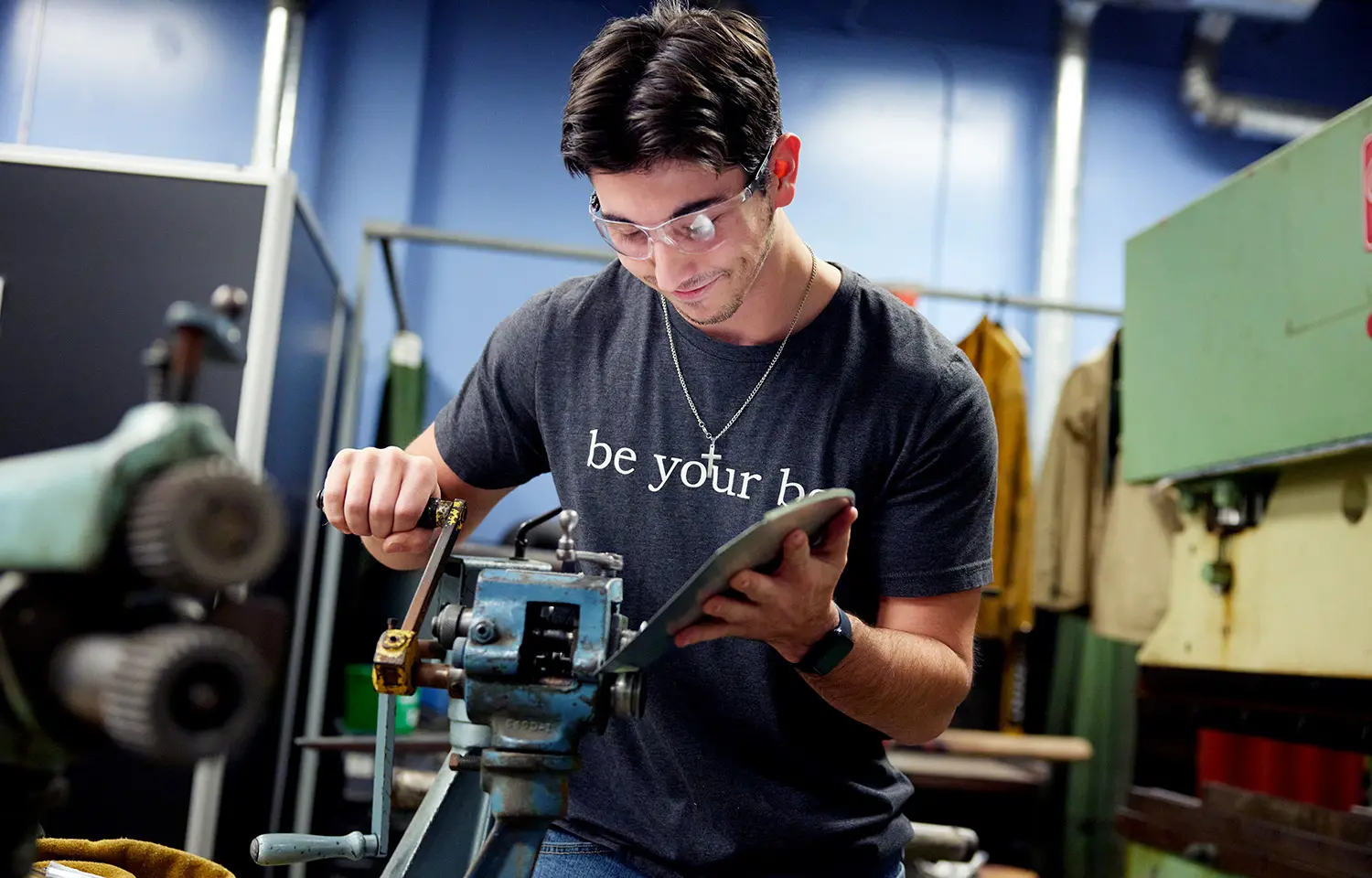

Hands-On Experience with Real-World Applications

We believe in learning by doing. Our state-of-the-art facilities offer hands-on training that mimics real-life scenarios, preparing you for the challenges and rewards of the industry. This practical approach enhances your learning experience and makes you a valuable asset to employers immediately.

Cutting-Edge Skills for a Booming Industry

The need for skilled sheet metal and HVAC professionals is soaring. Our comprehensive curriculum is designed to keep you ahead of the curve, ensuring you’re well-equipped with the latest techniques and technologies.

Transform Lives One Breath at a Time

Behind every efficient HVAC system, there’s an even more remarkable technician. Specialized HVAC technicians are the magicians who install, maintain, and repair these vital systems. By choosing this path, you’re not just picking a career; you’re stepping into a role that genuinely impacts people’s well-being, especially in critical settings like hospitals where clean air can make a life-changing difference.